Choosing between air- and water-cooled chilled water plants that best suit facility purpose and client needs requires expertise

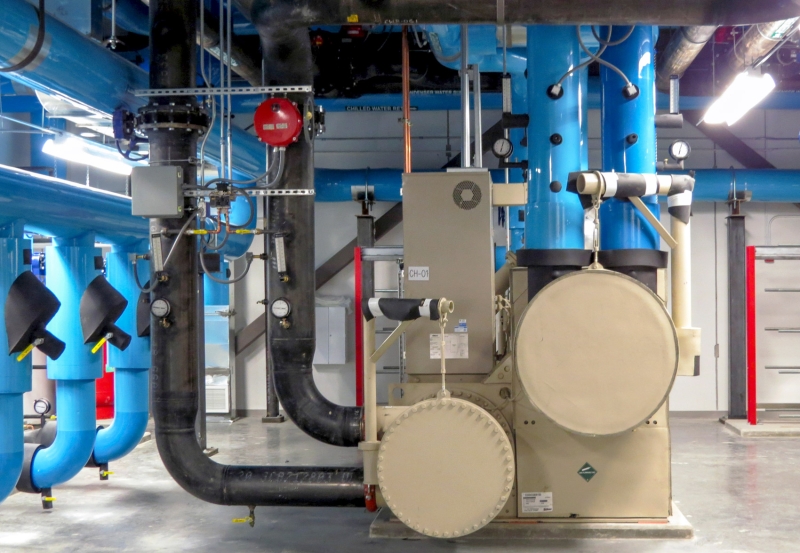

A common industry argument is that water-cooled chilled water plants often provide the most long-term benefits in energy and cost savings, despite the higher upfront investment. However, consulting engineers do need to know when to design an air-cooled chilled water plant or a water-cooled chilled water plant, which can be a challenge even for those with prior experience. While the two systems are similar, their fundamental differences answer unique project needs.

Five key considerations for selecting a chiller plant type are:

- Location of installation: available square footage, noise considerations and preference for indoor or outdoor installation site

- Future building use scenario: Is it a small office building likely to change owners in a few years or a large facility like a school that will be used for decades by the same owner?

- Operating efficiencies: building use scenario on a daily, weekly and monthly basis

- Installation costs: factor in local labor rates, shipping, time of year of installation and any site obstacles

- Life cycle analysis: plant location, weather conditions, electricity charges from the energy provider, building size and maintenance personnel training

Depending on the building type, usage and geographic location, chiller plant efficiency results will differ. For example, in the southern United States where cooling is required for longer periods of the year, a facility owner would incur higher energy savings per year with a water-cooled chiller plant compared to a similar owner in the north where heating is more of a concern. However, the cost of water could drastically reduce the differential, especially in areas where water is not abundant.

Content excerpted from an interview with Page Senior Mechanical Engineer Mark Stehney in Consulting-Specifying Engineer Magazine. To view the article, click here.

About Mark Stehney

Mark is a licensed Professional Engineer with more than a decade of experience in mechanical engineering. At Page, he works on complex commercial facilities from energy companies to data centers to hospitals. He has also achieved LEED AP BD+C accreditation.